The MGA With An Attitude

DOOR HANDLE (Outer) SPRING, MGA Coupe - CP-114B

On Sep 22, 2016, David A in Haywards Heath, Sussex, UK wrote:

"I rummaged in my tin of bits and pieces and found a tension spring that would fit inside the sleeve.

I unwound the eye and bent it outwards at a right angle to the axis of the spring. Its spring force is a bit less than the one in the other door but it returns the handle OK and stops it rattling. The spring characteristics as measured are the following, in inches:

I unwound the eye and bent it outwards at a right angle to the axis of the spring. Its spring force is a bit less than the one in the other door but it returns the handle OK and stops it rattling. The spring characteristics as measured are the following, in inches:

Wire diameter 0.053 Wire diameter 0.053

Spring OD 0.218 Spring OD 0.218

Spring length over coils and tangential leg 0.455 Spring length over coils and tangential leg 0.455

Spring length over eye, coils and leg 0.627 Spring length over eye, coils and leg 0.627

OD of eye 0.215 OD of eye 0.215

Spring is wound left hand Spring is wound left hand

Length of leg is unknown. Length of leg is unknown.

NOTE: The photo above is an original spring. Dimensions listed are for David's replacement spring (not necessarily as original). If someone can supply the original dimensions, I could make an engineering drawing for it, from which original type springs might be fabricated. Such springs are not particularly difficult to make by hand. In essence, you wind hardened and tempered spring steel wire tightly around a mandrel, and form the ends afterward. The mandrel has to be significantly smaller diameter than ID of the finished spring to allow for spring back of the wire when it is released.

Such springs can be made by commercial spring manufacturers. They set it up on a standard spring winding machine to make as many as you want. Individual springs are very cheap, but the set-up charge dictates manufacturing in larger quantities. If the set-up charge was $500, and each spring was $0.10, then 1000 pieces would be $0.60 each. The question then is, who would pay the set up cost to sit on a large inventory of parts for years before they might be sold (if ever). If you made 100 pieces they might be $5.10 each, or 10 pieces may be $50.10 each. That's when you buy some music wire and wind your own springs.

Here is a YouTube video of a bloke making a coil spring from wire scavenged from a steel cable (wire rope). Rather crude, but can work if you have the right diameter spring wire.

Here is a web page www.rctankcombat.com showing a process of hand winding a nice tight coil using some simple hand made tools.

And a manufacturing company www.springsfast.com that will make springs to order, if you can tolerate the price quote.

On Sep 23, 2016, David A in Haywards Heath, Sussex, UK wrote:

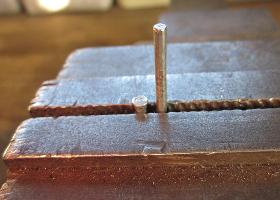

"I set out to make the spring. I found a piece of spring wire 0.054 diameter that was previously from a magazine spine binder and used a 0.10 diameter masonry nail with the point cut off as a mandrel and another as the anchor for the tangential leg, both fixed in the vice. I wound 7 turns to make the spring and another turn for the eye and cut off the excess. During turning and before cutting pull the wire tight and tap down on the coil with a hollow drift to press the coils together. Then turn up the last coil to make the eye and twist this across the diameter of the spring.

"The spring OD is 0.215 and I tested it for fit in a 7/32, 0.218 hole in a steel bar. I can't say that this will work in situ but for only a few minutes work it would be worth a try. Don't forget that the spring is left hand and I believe the leg is at a right angle to the eye, but the leg orientation needs to be checked out. The dimensions in my earlier post are for a broken original spring and should be checked if possible".

Addendum November 24. 2022:

Daniel Ross in Park City, Utah, USA wrote:

"I rechromed mine, but the springs were broken. This is my solution to the problem. Works well. -- Daniel

|