The MGA With An Attitude

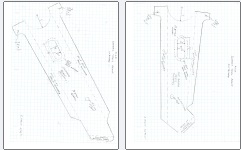

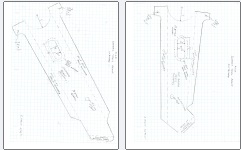

BATTERY FRAME WELDMENT - FR-202A

(For 6-Volt or 12-Volt Battery)

By popular demand, here are drawings to fabricate battery carrier bottom frames to repair or replace corroded battery carriers. Original parts were made from 14-gauge (0.075") steel sheet with rolled over edges for stiffening. These drawings show the parts made from 1-inch x 1/8-inch angle iron or 11-gauge (0.120") thick formed steel angle. I prefer the thicker material for long term corrosion resistance when exposed to battery acid, dirt and road exposure, and also for ease of construction. For concours show originality you should buy commercially available original style parts.

These drawings are for original size battery trays to accommodate original type 6-volt batteries. For use with Group 26 size 12-volt battery, extend the side bars 1/1-2 inches (as also noted on the drawings).

Click for larger images suitable to print on A-size paper.

Set printer for landscape mode, and "fit to paper".

Prefer small continuous welding all around both sides to seal against intrusion of battery acid and adhere paint. Grind welds on the top side to have flat surface under the battery. The formed offset shown immediately above goes under the chassis cross rail and allows the rest of the tray to be level and flush with bottom of frame.

|

Addendum, October 17, 2025:

When someone else needed one of these, I bought some angle iron and fabricated another one. This one is 1-1/2-inches longer than original to accept a Group 26 12-volt battery.

Addendum, November 3, 2025:

Addendum, November 3, 2025:

Added a new tech page for the Side Braces for battery carrier trays in the MGA chassis frame. This includes full scale templates with fabricating and assembly notes.

|