The MGA With An Attitude

POZIDRIV SCREWS and Driver Bit Design -- TS-101A

Phillips or Pozidriv?

by Norman Nock, British Car Specialists, Stockton CA

Looking through British cars parts books I found that many of the screws holding relays to the firewall were not Phillips(R) but Pozidriv(R) If you look at the part number in the factory book, you will see an identification telling you what type of screw it is. The search for information about these two classes of fastener has been frustrating, I visited libraries, book stores and tool suppliers. and the only answer that kept coming up was "sorry we don't have any information on that.

Finally. I found that there is still a Phillips Screw Company. I contacted them and after a few phone calls they realized I planned a technical article on the subject. They searched their archives to see if any articles have ever been written about Phillips and Pozidriv screws. To 'their knowledge. none ever has.

The story starts when Henry Phillips purchased a crude form of the recessed screw head concept from an inventor named J.P. Thompson. Phillips developed that screw into a workable form. He founded the Phillips Screw Company in Oregon in 1933, but never actually made screws. He had called on every established screw manufacturer in the US and was told simply that the screw could not be made.

Phillips then called on the American Screw; Company, a newcomer to the industry whose president personally became interested in the new product. despite the opposition of his engineers. who like others in the industry had insisted it could not be made. According to one printed report, the president of American Screw Company said: "I finally told my head men that I would put on pension all who insisted it could not be done. After that an efficient method was evolved to manufacture the fasteners and now we have licensed all other major companies to use it.".

|

|

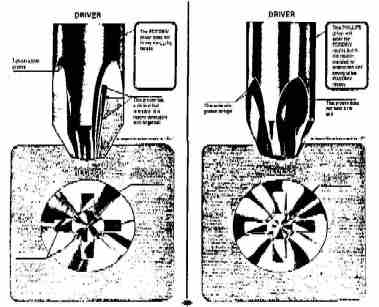

Close up of Pozidriv screwdriver and screw head (left) and Phillips driver and head show subtle differences between the two.

Phillips driver is designed to torque out as extra force is applied to fastener, preventing damage to screw head.

Pozidriv screw-driver incorporates visible ribs in the groove so driver will not torque out.

Material supplied by the Phillips Screw Company.

|

Use of the Phillips Screw spread through the automobile industry at a rapid rate. By 1939 it was used by all but two automobile manufacturers. By 1940 Phillips screws were used by the entire automotive industry. although one major manufacturer still would not use them on its passenger cars. Gradually the Phillips screw and screwdriver worked their way into other industrial applications. then consumer products, and eventually showed up in hardware stores

American Screw Company spent approximately $500,000 in the 1930s to produce the Phillips screw, and obtained patents on the manufacturing methods. It was the sole licenser of the process. By 1940 10 American and 10 foreign companies were licensed to manufacture the screw. The first off the assembly line were plated with gold and silver and made into a necklace for the president's wife and into a set of cufflinks. I have had the privilege to know the grandson of Henry Phillips who showed me the necklace and cufflinks.

American Screw Company advertised that these fasteners could speed up auto assembly lines because they could be used safely with power drivers--tools that might slip and mar a car's finish if used with conventional slotted screws.

These screws could also be driven with more torque and would hold together tighter than slotted screws. Phillips screws also centered more quickly and easily.

Mr. Phillips had come up with a recessed cross screw designed for efficient installation on an auto assembly line. The idea was that the screwdriver would turn file screw with increasing f1orce until the tip of the driver popped out--which brings us to the real reason behind the invention of this screw: It was designed to come out as if was driven in by screwdrivers so the screw head would not be ruined or broken off. When tightening a Phillips screw with a Phillips screw driver you will notice that when the torque gets to be too strong, the screw driver winds itself out of the screw--a feature built into the design of the system. A recent evolution of the Phillips design resulted in the patented ACR Phillips II(R)--a screwdriver that has ribs on both the driving and removal faces on the wings, making it ideal for assembly line and home use.

Development of a screw that would not "torque out"--the Pozidriv screw--came as the result of a joint effort of American Screw Company and the Phillips Screw Company. Since the Pozidriv screw will not torque out. any damage to the screw or tile surrounding surface is minimized. Phillips drivers should not be used with Pozidriv screws (and vice versa) as they tend to ride out of the recess and round the corners of both the tool and screw recess.

Early BN1s did not use Pozidriv fasteners. since they were introduced into the industry only about 1955-56.

Here's where to look for them in later Healeys: Door lock handle: door lock. door striker. heater control panel. vent windows. window frames, trunk stay brackets. truck lock. hood stay bracket. shroud brackets. hood striker bracket. regulator. and fuse box. in the parts book, Pozidriv screws will have the letters CMZ. PMZ or RMP in front of the part number.

Pozidriv screws also have slots cut into the face of the screw head to set them apart from Phillips screws.

Thanks to the American Screw Company and the Phillips Screw Company lot their assistance in the preparation of this article,

Philips, Pozidriv and ACR Phillips II are registered trademarks of Phillips Screw Company .

Austin Healey Magazine February 1996

This was doing well until the last full paragraph, and that part I have marked with red text. The Pozidriv patent was not applied for until mid 1959, so would not have been introduced or used anywhere before that.

|