The MGA With An Attitude

SU Carburetor Dating on MGA (1955-1962) - CB-127

Including sorting out the bits for correct assembly

Rev. 1.6 December 9, 2019 -- by Fred (Jack) Horner

Provided by and reproduced here with permission of the author.

Many thanks to Roger Payne from the Jag-lovers Forum where I found much of this information on year and date code and derived other MGA information from deduction. I also want to thank Don Tremblay for getting me started down this path as I did not have a clue where to start and he pointed me to the Jag-lovers Forum. My interest started when I decided to go through the various pairs of SU H4 carbs I have collected over the years, and then figuring out when production changes occurred to ensure all the parts matched for that particular car.

Figure 1

The SU H2, H4, H6, and H8 have a stamping on the casting of the carb body where the throttle plate flange meets the intake manifold at the top of the casting (See figure 1). There is an alphabetic character followed by a number. The alphabetic characters start at A" and go to Z" but some letters are not used. The numbers are from 1 to 12 representing the month in which the carburetor was built. I have seen at least two exceptions were the number was 13 for a 1956 and for a 1961, so, this needs further study. Also note that although the date stamp is put on the carb by SU, it may have taken a bit of time before it was actually installed on a car on the production line. Also remember that the model year of the cars on the production line often started in the year before the model year and went into the model year dates. So, the carb date code may not match the model year of the car exactly and the month of production may or may not match the month of production of the car.

The SU H2, H4, H6, and H8 have a stamping on the casting of the carb body where the throttle plate flange meets the intake manifold at the top of the casting (See figure 1). There is an alphabetic character followed by a number. The alphabetic characters start at A" and go to Z" but some letters are not used. The numbers are from 1 to 12 representing the month in which the carburetor was built. I have seen at least two exceptions were the number was 13 for a 1956 and for a 1961, so, this needs further study. Also note that although the date stamp is put on the carb by SU, it may have taken a bit of time before it was actually installed on a car on the production line. Also remember that the model year of the cars on the production line often started in the year before the model year and went into the model year dates. So, the carb date code may not match the model year of the car exactly and the month of production may or may not match the month of production of the car.

As an example, the letter and number on my 1955 MG TF carbs is L7. They both match. L represents a production date of 1954 and the 7th month (July). The first TF 1500 was built in July of 1954. My TF is an early production 1500 number TF/6545, (first is TF/6501). So, in this case the SU carb dates match the production date of my TF.

Table 1 shows the letter corresponding to the year. Notice that I, J, and O are not used. I donít know why except that perhaps because of the stampings they may not fully impress and could be confused with other letters. Also V, W, Y, and Z are not used,nobody knows why. Roger Payne says that only the X is specifically mentioned in any SU documentation and is definitely used for 1962. I have included Rogerís extension of lettering for the SU H series as far as he went with it. The letter Q is often seen on H4 and I believe these were factory replacements/spares as I have seen Q on several different models of carbs.

Table 1

| A | 1945 | N | 1956 |

| B | 1946 | O | not used |

| C | 1947 | P | 1957 |

| D | 1948 | Q | replacement |

| E | 1949 | R | 1958 |

| F | 1951 | S | 1959 |

| G | 1951 | T | 1960 |

| H | 1951 | U | 1961 |

| I | not used | V | not used |

| J | not used | W | not used |

| K | 1953 | X | 1962 |

| L | 1954 | Y | not used |

| M | 1955 | Z | not used |

I have not seen many cars with the correct date stampings matching the production month of the car, but I am still looking for matching examples. In many cases, unless one has the Heritage certificate one may not know what month their car was manufactured. There are some sources such as the "Original" books by Clausager which provide some information about production dates.

I have not seen many cars with the correct date stampings matching the production month of the car, but I am still looking for matching examples. In many cases, unless one has the Heritage certificate one may not know what month their car was manufactured. There are some sources such as the "Original" books by Clausager which provide some information about production dates.

The MGA carburetors for pushrod engines have two different specification numbers based on the 1500 (part number AUC784) and 1600 including the MK-II (part number AUC943). These numbers are found on aluminum tags attached to the float bowl cover nuts.

There were two companies making the castings (I think both located in Birmingham, England). There is P.D.C. (Precision Die Casting) which appears to have made all of the carburetor body castings for the MGA (and other castings). This company is still in business and is Avon PDC part of the Rical Group. There is also MCL. I donít have a current reference for them, so, I donít know if they are still in business or have been taken over by another company (and I cannot define the initials). I will try to reference any differences I found between the castings of the two companies.

Carb Bodies

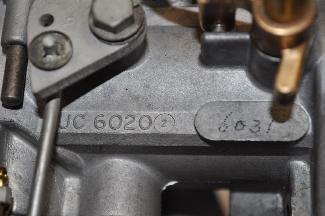

Regarding the bits that make up the carburetor I will focus on the SU H4 used in the MGA push rod engines. The carburetor body has part number AUC6020 cast into the lower right side of the casting (See Figure 2) on those cast by PDC. At the end of this number is a circle which is used to indicate a particular revision to the casting. If there is a letter in this circle it is usually a modification to the casting which does not affect the part number. After this is an oval flat area to engrave a specific part number depending on machining of the part.

The MGA front carb has 6031 etched into the oval. The rear carb has 6033. The front carburetor has several machining processes performed on it which are unique to the front carb. First, I will mention that on the top of the carb body near the rear throttle damper housing screw mounting is an additional flange and hole that has been removed to allow for the function of the choke fast idle cam. Also on this same right side of the carb is a boss that is drilled and tapped for the pivot screw of the choke cam. If no screw is present then there is a hole all the way through the casting wall into the throat of the carb in front of the throttle plate. Opposite this drilled boss is another boss that has been machined down almost flush and is not used.

The rear carburetor has none of these machining changes, but differs in that the angle casting at the rear left near the mounting flange at the bottom, is drilled and tapped for the vacuum advance tube. The front carb does not have this drilling. This same casting part number is used in other British cars of the same period (such as Austin Healey 100s and Triumph TR2) and the etched in number changes based on different machining changes done.

Figure 2

This is a late production carb body (1959 and later) as indicated by the 2 in the circle. Earlier bodies had a Z in the mod circle. I have also seen AC, but I am not sure these were on MGAs. MCL also cast carb bodies but the AUC6020 was cast along the top of the right side of the body just below the suction chamber seat. No modification number present after the part number.

This is a late production carb body (1959 and later) as indicated by the 2 in the circle. Earlier bodies had a Z in the mod circle. I have also seen AC, but I am not sure these were on MGAs. MCL also cast carb bodies but the AUC6020 was cast along the top of the right side of the body just below the suction chamber seat. No modification number present after the part number.

As far as I know, all the carburetor bodies are the same throughout the MGA pushrod

engine production. Where differences are found are in some of the other bits that are

assembled onto the body of the carb. I will start out with the float bowls.

Float Bowls

The float bowl part numbers are rear: 3495 and front: 3496. Later production float bowls are AUC3495 and AUC3496. The PDC early float bowls had a part number followed by a modification letter such as M or K (from observation) in the round blank after the part number followed by PDC but when they started producing the float bowls with an AUC prefix then the PDC appeared on the opposite side of the float bowl (AUC3495 and AUC3496). (See Figure 4) PDC float bowls had the number on the front of the front float bowl and the back of the rear float bowl.

On the float bowls produced by MCL there was an MCL cast in after the part numbers of 3495 and 3496 (with a blank circle after the number). I have only been able to find one style float bowls produced by MCL. MCL float bowls had the part numbers on the front of the carb on front and rear carb float bowls. (See Figure 3)

Figure 3![]() Figure 4 Figure 4

Float Bowl Covers

The float bowl covers were made by both companies and started out with a single boss which in pre-MGA carbs was drilled through and contained a tickler pin (in order to prime the engine. By pushing down on the pin the float was depressed causing the fuel level to rise about the needle seat and allowing fuel to go into the carb. Some early MGAs may have had a tickler pin, but I have not verified this. The MG TF and AH 100 from 1955 and most earlier MGs had the tickler pin. All of these tickler pins were brass.

The early float bowl covers have the casting number 1160 (rear) and 1161 (front) cast into the top of the inlet housing. Those from MCL had no casting modification letter but PCL casting have an L before the number or after the number. I think the castings with the letter following the number are the later version. (See Figure 6)

Figure 5![]() Figure 6 Figure 6

MCL castings have three bosses that were not drilled through. (See Figures 7) Don Tremblay (a die cast expert) says that these are ejection pins and the difference is the mold style (different from how PDC did their molds). The casting number did not change. All that I have seen with the three bosses were made by MCL. In late 1959 MCL started using castings with the part number rather than the casting number. The front cover had AUC4261 and the rear cover only 4260 (notice no AUC before the number). I have found these on carbs stamped with the S and T. (See Figures 8)

Figure 7![]() Figure 8 Figure 8

Starting also in late 1959 PDC castings have an unmarked blank area raised on the inlet of the cover. On the underside it is marked AUC4260 or AUC4261. Donís MGA 1600 built in early 1960 has this style. This was also used on Jaguars around 1960. I also saw these on another 1960 MGA. (see Figure 9 and Figure 10) All MGA MK-II carbs I have seen have the MCL covers with three bosses and the part number.

Figure 9

Figure 9![]() Figure 10 Figure 10

The early MGA carbs had a brass float bowl cover retaining nut. The later cars had steel nuts. I have seen the brass nuts on 1957 and earlier but 1958 and later should all be steel. These were always the "long" style to accommodate the overflow/breather pipe. (See Figure 11)

There are also two styles of mounting the float bowl to the carb body. All the MGAs had the single banjo bolt and a single cupped washer up to somewhere in 1959 at which point the banjo bolt was replaced by a drilled stud bolt with two flat washers of different internal diameters and a nut to secure the washers, seals and float bowl onto the carb body. The earliest carb I have seen for a MGA 1600 is S2 and it has the banjo bolt. By October of 1959 the MGA 1600 and later carbs starting with an S for the year were of the drilled stud type. (See Figure 12)

Figure 11![]() Figure 12 Figure 12

Pistons and Suction Chambers (Dash Pots)

The suction chambers for the H4 have three securing tabs. There is a damper rod at the top of the chamber. The early chambers were drilled though the gusset at the top to allow the vacuum to work on the piston. The damper rod cap was not drilled. It was marked Oil Reservoir". The suction chamber had a Z stamped near the damper rod tower at its base. Sometimes there were other letters stamped as well. I donít know what these letters mean. Later damper rod cover was unmarked. This damper rod was longer than those marked Oil Reservoir".(See Figure 13) In 1959, for the MGA 1600, the suction chamber was changed to not have the drilled through gusset and the damper rod cap was drilled though and a 0 (zero) stamped in the cap (to indicate a slightly longer length to the damper rod). (See Figure 14) These suction chambers had no markings on top. Do not mix the two types of damper rod and suction chamber as the carburetor will not function correctly!

Figure 13![]() Figure 14 Figure 14

The pistons all remained the same with a guide slot on the left side of the piston and the needle secured with a set screw opposite the guide slot. There are two air inlets cut into the back side of the piston. There is an earlier style piston which is functionally the same used on the MG TF 1500 and AH 100, but the air inlets come straight down in the piston bottom whereas the MGA has a notch toward the back. I donít know if this was for better control of the airflow, but there is a small difference. In any case, very early MGAs may have this type of piston.

Figure 15![]() Figure 16 Figure 16

A lifting pin is assembled in the carb body to lift the piston for making adjustments. By lifting the piston by the pin the revs of the engine will change and one can determine the mixture adjustment of the needle. In 1955 the lifting pin was made of brass. Some of the early MGA carbs have this brass lifting pin. By 1957 the pin was a steel pin with a needle end toward the piston. (See Figure 15) 1958 changed to a larger end steel lift pin. (See Figure 16)

A lifting pin is assembled in the carb body to lift the piston for making adjustments. By lifting the piston by the pin the revs of the engine will change and one can determine the mixture adjustment of the needle. In 1955 the lifting pin was made of brass. Some of the early MGA carbs have this brass lifting pin. By 1957 the pin was a steel pin with a needle end toward the piston. (See Figure 15) 1958 changed to a larger end steel lift pin. (See Figure 16)

Other bits of interest

The early carbs on MGAs had brass cheese head screws securing the Suction Chamber whereas all later cars had steel (probably starting in 1956). These screws had an internal toothed lock washer beneath the head although some rebuilders say there should not be washers there.

The idle adjustment screws on early carbs up through 1957 had knurled standard (flat blade) screws. All later cars had a small cheese head screw.

The early carbs up through 1958 had brass cotter pins for all of the pivot point clevis pins and the choke fast idle rod. I think most rebuild kits now come with steel cotter pins. Later carbs had a "Starlock" washer. The earliest date code I have seen these used on is S2, but they may have been used earlier. According to Moss Motors the official start of use of this washer is engine number 16GAU/31660 but I have seen these on earlier carbs in 1959 and they may go as far back as 1958. I am not sure how this engine number was determined as it is the last of the MGA 1600 engines before the MK-II in March 1961. These "Starlock" washers are used on either end of the choke fast idle cam actuating rod and on the pin that connects it to the choke actuating lever. These are also seen on the clevis pin for the jet lever as well. Up until sometime in 1958 the carbs only had cotter pins. Note that the clevis pins with a hole and cotter pin are interchangeable with the cotter pin and "Starlock" (with no hole for the cotter pin), so, some carbs may have been rebuilt with the incorrect pins in the past.

Conclusion

That covers the changes which I have identified between the beginning and end of production of the MGA. Peter Thornley (son of John Thornley, the General Manager of MG from 1952 to 1969), states that the SU factory in Birmingham, England sent the finished carbs to the engine plant in Cowley and then the engines were sent completed to Abingdon for installation into the MGAs (and other marques). This was a "just in time" inventory method and may explain why there is often a difference of several months between the date on the carburetors and the production date of the MGA. If the SU date stamp is after the production date of the MGA, then they are not the correct carbs for the car (or are a replacement set). I will revise this document as verified differences can be determined from "unmolested" MGAs with original carburetors. Again, many thanks to Roger Payne and his analysis of the Jaguar carburetors which got me started down this path. I will expand this analysis to include earlier MGs and later MGs as information becomes available. -- Fred (Jack) Horner

|