The MGA With An Attitude

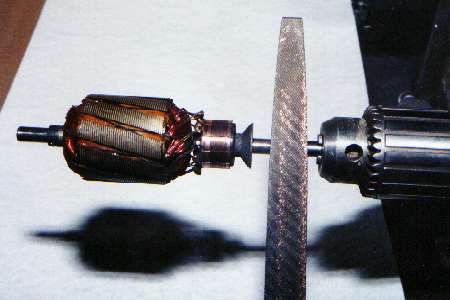

This is a picture of the motor armature chucked up in an electric drill for the purpose of cleaning up the copper commutator. With the parts in this orientation I run the drill in reverse (anticlockwise) and pass the file forwards across the commutator. Please do not file on the output shaft, and be careful not to damage the soldered wire terminals at the left end of each of the commutator segments.

After the copper segments have been filed smooth you may like to polish the surface slightly with emery paper, but a fine tooth file will usually do a sufficient job on its own. After smoothing the commutator you should clean out the copper shavings (electrically conductive) and/or emery powder (abrasive) from in between the copper segments. This may require more a little mechanical scraping, more than just an air blast.

|