The MGA With An Attitude

PRIMING THE OIL SYSTEM, MG B-Series Engine - OF-103

after engine work to assure oil pressure on startup.

At 09:20 AM 5/22/2000 -0500, Andy Badeker wrote:

> .... apparently the oil pump lost its prime. ....

>.... I then tried putting the oil-pressure hose in a quart of oil, jacking up a rear wheel and putting the car in 4th and turning the wheel backward, hoping to suck some oil in via the hose: No luck.

First, see oil flow path description here:

http://www.mgaguru.com/mgtech/engine/of101.htm

The oil pressure hose is tapped off the back of the main oil gallery in the block. This is just before the feed to the main bearings, but well along in the supply path. To get there the oil from the pump first travels across the back of the block, then through the external oil line, through the oil cooler (if you have one), then through the oil filter and back into the main oil gallery in the block.

Each time I have reassembled a dry engine I have primed it by using a trigger pump oil can to inject oil at the oil pressure hose port on the block. I keep pumping until I can feel a significant increase in flow resistance, which can take about a pint of oil at that point. This fills the main oil gallery and gives oil to the main bearings. If nothing else this should provide peace of mind while you are cranking on it trying to get the pressure up. It also tries to flow oil backwards through the filter and oil cooler back into the rear of the block, and then back to the oil pump. However, the oil filter generally has an anti-back flow check in it so the oil won't go back that way anyway. This will NOT provided a prime to the pump.

You may need to try priming it closer to the oil pump. Disconnect the large external oil line at the back corner of the block, fill the port in the block with oil, and then rotate the engine backwards to draw the oil backwards into the oil pump. Always works for me. But, if it doesn't draw that way, try applying a little pressure to assist the back flow into the pump.

During repair operation the engine was completely drained of oil with the oil pan and oil pump removed and the engine innards being washed out with solvent. The oil pump may have retained not much oil after lying on its side on the bench for 3 days, but was probably at least still wet internally. While the engine was still on the engine stand after reassembly I topped it up with oil and proceeded to rotate the innards with the MGA hand crank. After fewer than 20 turns of the crank (10 turns of the oil pump) oil came pouring out of the port at the right rear corner of the block. After installation in the vehicle I pre-filled and installed the oil filter, connected the oil cooler lines and cranked it with the starter. After only 15 seconds of cranking without spark plugs it had oil pressure reading on the gauge. No doubt about it having a good oil pump. But this does serve to show that even with a well primed oil pump and a full oil filter it can still take an appreciable amount of time to fill the external lines and oil cooler before you will see pressure on the gauge. So don't be discouraged if it takes a minute of cranking before the pressure comes up.

On 3/10/2016, David Adams wrote:

On 3/10/2016, David Adams wrote:

"This is my oil prime receptacle with female thread to fit onto the large port's nipple. I put in one pint of oil and turned the rear wheel backwards (plugs out) for what seemed like a long time, and next time I looked it was all gone. I spun the engine and my pint of oil reappeared in the bottle so I pumped it back again, reconnected the piping, spun it until oil appeared at the gauge nipple, connected the pipe, spun it some more until oil appeared at the gauge union, made the joint, spun it some more and got 55 psi on the gauge. Marvellous! Thank you very much for your help".

Nice custom made tool, but it doesn't need to be so exotic. A hose that can push tight into the fitting on the engine works, along with a bottle with a nozzle (common for gear lube). Or just a small funnel (like I use for filling the gearbox).

On 10/13/2020, John H Francis with a Twin Cam wrote:

"I am having trouble getting any oil to flow. With the carbs on the other side I can't easily get to the pipe on the back of the engine to put oil in there. However, I can get to the pressure relief valve. I have poured about half a pint of oil into the relief valve hole without the valve in place. I think this should go straight into the pump? However, I still can't seem to get any oil to flow. I have tried rotating the engine backwards as well to see if that helps. -- Should my technique work"?

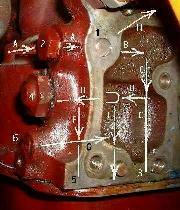

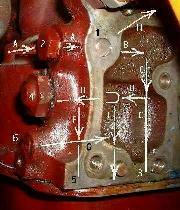

Probably not. Removing the P/R valve and pouring oil in there should just pour it directly into the sump via the P/R valve return port. Leave the P/R valve in place to block that port. -- Remove the hex plug immediately above the P/R valve cap plug (plug 2 in this picture). Pour oil in there, and turn the engine backward a couple of turns to draw oil backward into the pump. See oil flow path here: http://mgaguru.com/mgtech/engine/of101a.htm

Probably not. Removing the P/R valve and pouring oil in there should just pour it directly into the sump via the P/R valve return port. Leave the P/R valve in place to block that port. -- Remove the hex plug immediately above the P/R valve cap plug (plug 2 in this picture). Pour oil in there, and turn the engine backward a couple of turns to draw oil backward into the pump. See oil flow path here: http://mgaguru.com/mgtech/engine/of101a.htm

On 10/13/2020, John H Francis wrote:

"Thanks, your suggestion worked a treat easily".

|