The MGA With An Attitude

LOUVERED PANELS For Inner Fenders - TC-117

BMC part numbers AFH5844 (R/H) and AFH5845 (L/H)

In September 1958 the Twin Cam inner wheel arches were fitted with detachable panels to facilitate access to the engine compartment. These were introduced at roadster #592 and Coupe #594. The vent louvers were double punched from opposite sides of the panel to have larger openings. Using a single sided punch this requires 7 punch hits to make 3-1/2 louvers. Pictures below show a correctly louvered panel on left and an incorrect aftermarket panel on right.

A supplier of good panels is: KAS-Kilmartin in Australia. They are sold by agents in most countries that have large numbers of MG's (such as the USA). An email to the company should give you a US source. See their web page at:

A supplier of good panels is: KAS-Kilmartin in Australia. They are sold by agents in most countries that have large numbers of MG's (such as the USA). An email to the company should give you a US source. See their web page at:

www.kas-kilmartin.com.au

Their part number is MGA131 (R/H and L/H).

If you want to make your own panels, a special punch is required. I do not know where to get this tool.

The Twin Cam SPL lists these part numbers for attaching front inner wing vent panels:

PJZ1003 Screw fixing panel (14 ea)

PFS310 Nut for screw (14 ea)

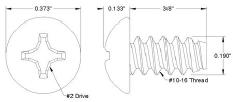

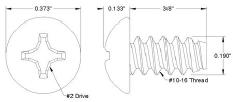

The original screws were Pan head, Phillips drive, #10 X 3/8 inch coarse thread screws with a truncated (blunt) tip end. The blunt nose is a safety feature to protect hands and arms when working in the confined space of the engine bay. So far I don't know if there is any modern equivelant of this screw style (but it must exist somewhere).

The original screws were Pan head, Phillips drive, #10 X 3/8 inch coarse thread screws with a truncated (blunt) tip end. The blunt nose is a safety feature to protect hands and arms when working in the confined space of the engine bay. So far I don't know if there is any modern equivelant of this screw style (but it must exist somewhere).

A commonly supplied modern screw type would be the Pan head, Phillips drive,#10 X 3/8 inch sheet metal screw (Type A). This is nearly identical, except it has a sharp point with potential of causing personal injury when working in close quarters.

A commonly supplied modern screw type would be the Pan head, Phillips drive,#10 X 3/8 inch sheet metal screw (Type A). This is nearly identical, except it has a sharp point with potential of causing personal injury when working in close quarters.

Thanks to a note from Aaron Coolidge, this screw is identified as Type B Self Tapping Screw, #10-16 straight thread with tapered nose and blunt tip. It has a larger root diameter and finer pitch than the common Type A pointed tapping screw (which would be #10 with 12-tpi), so the mating captive nut will also need to match the Type B thread form. These screws are apparently common with aircraft parts supplies, but also available from McMaster-Carr here in the States, McMaster-Carr part number 90056A240

Thanks to a note from Aaron Coolidge, this screw is identified as Type B Self Tapping Screw, #10-16 straight thread with tapered nose and blunt tip. It has a larger root diameter and finer pitch than the common Type A pointed tapping screw (which would be #10 with 12-tpi), so the mating captive nut will also need to match the Type B thread form. These screws are apparently common with aircraft parts supplies, but also available from McMaster-Carr here in the States, McMaster-Carr part number 90056A240

U-nuts go on the edge of the removable panel, which in turn goes inboard of the inner fender, with the screws installed from the outside. When you remove the screws, the U-nuts stay attached to the removable panel. No concern for flush fit or sealing, as the removable panels are louvered for ventilation anyway. Try McMaster-Carr part number 94810A007.

U-nuts go on the edge of the removable panel, which in turn goes inboard of the inner fender, with the screws installed from the outside. When you remove the screws, the U-nuts stay attached to the removable panel. No concern for flush fit or sealing, as the removable panels are louvered for ventilation anyway. Try McMaster-Carr part number 94810A007.

In the USA we call the press-on nut Tinnerman fastener, which is a brand name that has come to be used commonly for almost any kind of sheet metal clip. The more generic name is U-Nut for a clip-on nut that will accept a threaded fastener. Part number may have changed later to GHF713, which is another Tinnerman type clip-on nut that accepts the same screw (but might be for thicker sheet metal). In the USA we call the press-on nut Tinnerman fastener, which is a brand name that has come to be used commonly for almost any kind of sheet metal clip. The more generic name is U-Nut for a clip-on nut that will accept a threaded fastener. Part number may have changed later to GHF713, which is another Tinnerman type clip-on nut that accepts the same screw (but might be for thicker sheet metal).

|