The MGA With An Attitude

PISTON-VALVE CLEARANCE in Twin Cam Engine - TC-303C

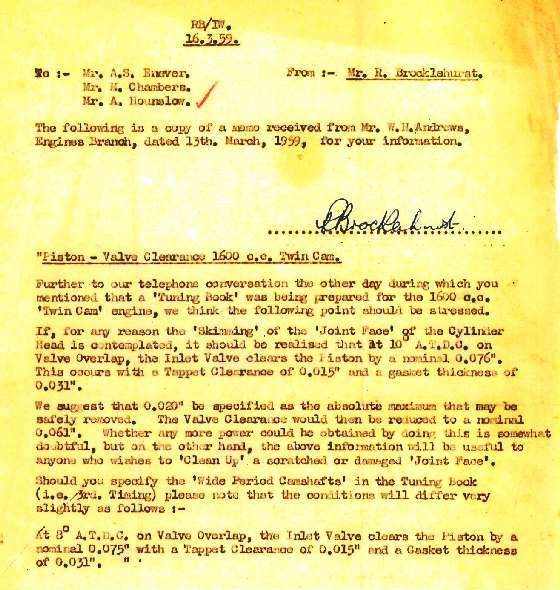

This is an internal memo originating from Mr. W. H. Andrews, Engine Branch, referencing a small allowance for "skimming" (decking) the Twin Cam cylinder head or engine block (which is noted in the Engineering Technical Data book as being not allowed). Valve to piston clearance should be checked carefully any time the head or block is skimmed, or any time camshaft or valve work is done.

Click for larger image - (200-KB pdf)

Addendum September 4, 2017:

As a suppliment to the above memo:

The method of checking the valve to piston clearance when using the high compression (9.9 CR) pistons and standard camshafts. This information is for when rebuilding an engine with an unknown history.

Firstly some background: At what point is a Twin Cam valve fully open?

With an inlet valve (similar calculation but in reverse for an exhaust valve) it opens at 20 BTDC and closes at 50 ABDC. It is therefore be open for 20+180+50=250 degrees. With a symmetrical shaped lobe it will be fully open 125 degrees after it starts to open. The engine will be 105 ATDC (125-20) when the piston will be more than halfway down the bore. Many people believe that tests are carried out at TDC, but with valve overlap the point when the piston is closest to valve is in fact at 10 degrees ATDC.

The correct test is as per the factory method. After torquing the cylinder head down and setting the valve clearances, at 10 degrees ATDC with the chain attached check the clearance by depressing the tappet. Your measured clearance should be compared with the factory specification as many things influence the clearance, cylinder head skimmed, piston crown shape non-standard, different tappet clearances, different valve lengths, different compressed thickness of the head gasket. This is the true running clearance.

|