The MGA With An Attitude

ALTERNATE VALVE SEALS - CH-202

Before expounding on alternate valve seals, we should understand how the original ones work. In the picture at right, notice the original seal, which is just a small O-ring, and original deflector, which is a thin metal shell fitting inside the valve spring and close around the top of the valve guide. The O-ring should be installed inside of the spring retainer cap and against the bottom of the cotters. This makes a seal between the bore of the spring cap and the valve stem to prevent oil on top of the spring cap from running down the valve stem into the guide. The deflector serves to shield the top end of the guide from oil splash from the springs. This arrangement served well for decades, but does allow a small amount of oil into the valve guides. When the guides are in good condition the oil infiltration is minimal and serves to lubricate the original iron valve guides. (As a matter of curiosity, use of the oil deflector was discontinued in December 1962 after production of 4284 MGB with 1800 engines).

As the guides wear with extended use, the working clearance increases and more oil can get down through the guide and into the port area of the cylinder head at the valve head. This results in increased oil consumption and carbon build up on the valve heads and stems in the area of the bottom end of the guides. A lot of carbon buildup here can disrupt air flow and cut engine power significantly. If guide wear is bad enough, excess oil can get sucked down the intake guides under vacuum and cause carbon buildup in the combustion chamber, and smoke and/or oil droplets being blown out the exhaust. Carbon deposits in the combustion chamber can cause hot spots and engine run on after shut down. In severe cases, heavy deposits in the combustion chamber can also cause pre-ignition (spark knock or pinging) or detonation (the LOUD kind that eats spark plugs and pistons). Carbon deposits in the piston ring grooves can cause sticking of the piston rings, which can in turn cause loss of compression, oil burning, and compression blow-by through the crankcase. For MGA, early MGB, and other similar vintage engines, this can blow oil into the air cleaner via the (intended) intake breather hose, and out the draft tube at the front tappet cover to the under side of the car. For later engines with sealed crankcase and a PCV valve, blow-by can deposit oil into the intake manifold where it also gets sucked into the combustion chamber.

Mind you, those nasty things should only happen with a badly worn engine that may be in need of an overhaul anyway. But even then the installation of improved valve seals can cut oil consumption dramatically, which might be enough to get by for a while longer before biting the cost of a complete overhaul. It has in recent years become general consensus of opinion that it is a good idea to install up-rated seals on the intake valves of a stock engine with iron guides. If bronze valve guides should happen to be installed during the course of reworking a cylinder head, then the preferred target might be zero oil in the guides, as the bronze material is self lubricating when running against smooth steel valve stems.

Below we have larger than life pictures of a few of the available alternate valve seals, all of which grip onto the top end of the valve guide to seal around the valve stem. Almost any umbrella seal will seal as well when new. The Teflon ones will have less friction on the valve stem (which may not be very important to the operation of the engine). But the Teflon ones will also last much longer with less wear, especially with high operating temperatures (like my towing the trailer on the expressway) where rubber bits may suffer premature embrittlement. I have used several different types of valve seals. Looking at picture, refer to the numbers 1-4.

Notice with the installed views below the increased gap in the bottom retention band as the seals are stretched over the valve guide. Also note that use of these seals requires removal of the original oil deflector, in which case you should also get the later model spring cap with larger pilot diameter to fit the ID of the inner valve spring.

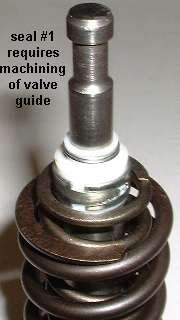

Early on I used some all-Teflon parts that would have almost infinite life under high temperature conditions. With not much experience I told the shop I wanted to use Teflon seals, and this is what they installed. See seal #1

All Teflon seal -- fits 11/32" stem and guide turned down to 1/2" OD at the top:

Perfect Circle -- ? Perfect Circle -- ?

Sealed Power -- 2018R Sealed Power -- 2018R

TRW -- VP66 TRW -- VP66

Since Teflon has very little spring resiliency when used at elevated temperatures, these seals had a spring wire or flat metal band constrictor in two places, around the top for seal pressure on the valve stem, and around the bottom to make it hang onto the valve guide. They work fine, but have large wall thickness (with the metal band), so the top of the guide had to be reduced in diameter a little to allow this type seal to fit inside of the inner spring of the dual spring set up. That added cost for machining the guides. The seals also cost about $3.50 each, $28 for a set of 8 (some years past, prices may vary).

The next time around I had rubber seals in about the same configuration with a small Teflon insert in the top for the stem seal. Sorry no picture of that one.

Rubber seal with Teflon insert at stem -- fit 11/32" stems and guides turned down to 1/2" OD at the top:

Perfect circle -- VS10 Perfect circle -- VS10

NAPA -- VS10 NAPA -- VS10

BAF -- 72 BAF -- 72

These still required the reduced guide diameter. They also worked as well as the all Teflon seals, and were a little cheaper, about $3.00 each.

Next time I had in mind to find a local retail source for the seals rather than relying on the engine shop to supply them. So I checked out a local Trak Auto (when they were still in business) late one evening after most other parts stores were closed. I took a valve and a valve guide along to use for example and for test fitting seals. The blokes behind the counter had no idea how to find anything in the store without a stock car make and model and engine spec to look up in the book, but they did finally turn me loose for a while at the shelf in back where the valve seals were stocked. I sat on a step ladder near a top shelf for 45 minutes trying every valve seal they had, and finally found three that would fit, one to fit the reduced diameter guide and two that fit the full diameter guide.

The first was similar to what I had used before, size to fit a reduced diameter guide, but all rubber with one metal band to hold it on the guide.

All rubber seal with metal band at guide -- fit 11/32" stems and guides turned down to 17/32" OD at the top:

Felpro -- SS_13360 (set of 8 pieces R_13360 from Trak Auto) Felpro -- SS_13360 (set of 8 pieces R_13360 from Trak Auto)

Fits Pontiac 6 & V6, 230 & 250, 1966-69 Fits Pontiac 6 & V6, 230 & 250, 1966-69

Pontiac & Olds V8, 325, 350, 389, 400, 421, 428, 455, 1959-79 Pontiac & Olds V8, 325, 350, 389, 400, 421, 428, 455, 1959-79

I bought one set of those for spares for the prior engine. Used them up long ago, so sorry, no picture here either. A single "S" in the part number indicates one Seal. Double letter "SS" in the part number indicates a Seal Set (8 pieces). Cross reference says these fit a bunch of GM 6 and 8 cylinder engines, so pretty common parts, and cheap too, but they still require machining of the valve guides.

Then I went looking for a seal that would fit on the standard diameter guide without machining. First find was a no-go. See seal #2. Out of the box and loose this one drops right through the inner valve spring. But when it's stretched a bit over the valve guide it does not fit inside the inner spring, not even close, so forget that one, just to let you know what to watch out for. The thick metal bands would make it too large, but additionally there is a stepped out rubber flange at the bottom about the same OD as the metal bands. Logo molded on top says "USA 3104 38" but no brand name.

The next was also for full diameter guides but with thinner skirt wall and small wire bands, so it would work on the full diameter guide and still fit inside of the dual springs. Good deal, no machining required. This is one of the good guys. See seal #4. (Also see exception note below in addendum 6/29/09).

All rubber seal with metal band at guide -- fit 11/32" stems and stock size guides 9/16" OD:

For the MGA- MGB (not for Midget A-series engine 1098-1275cc) For the MGA- MGB (not for Midget A-series engine 1098-1275cc)

Victor 8B45404 Victor 8B45404

NAPA B45404 NAPA B45404

That one is all rubber with flat top and a short seal neck inside about 1/8" long with about 10 tiny seal ridges and valleys. The top wire constricts the top of the seal to fit snugly enough on the stem to have a few ounces of axial drag on dry metal. A touch of oil and a little running time would free that up some, probably cut the drag in half. The one in the picture came out of a package labeled

"Victor Reins 8 B45404" (8-piece set) "Victor Reins 8 B45404" (8-piece set)

On top of the seal itself is molded

"BAF BBR 57" and a tiny brand logo that looks like "PC" inside of an ellipse, which might be Perfect Circle. But on the packaging card it says "Dana Corporation". "BAF BBR 57" and a tiny brand logo that looks like "PC" inside of an ellipse, which might be Perfect Circle. But on the packaging card it says "Dana Corporation".

Anyway, this is commonly known as the "Victor Umbrella Seal", even though it doesn't specifically say that on this package. It also turned out to be the cheapest at about $1.50 each, $12 for the set. At the time I wasn't too fond of the all rubber construction, but it did have a part number, and I was able to back reference it in a "where used" table to find what engines it would fit. Turned out to be a bunch of Ford V8s, so also very common. From there I went to the car and engine designations to look up part numbers for more seals from different manufacturers, then back to the shelf for another look. Anyway, this is commonly known as the "Victor Umbrella Seal", even though it doesn't specifically say that on this package. It also turned out to be the cheapest at about $1.50 each, $12 for the set. At the time I wasn't too fond of the all rubber construction, but it did have a part number, and I was able to back reference it in a "where used" table to find what engines it would fit. Turned out to be a bunch of Ford V8s, so also very common. From there I went to the car and engine designations to look up part numbers for more seals from different manufacturers, then back to the shelf for another look.

It took just 5 minutes with the part numbers to hit gold. The last one was similar in configuration and dimensions, rubber with thin skirt wall and flat top, but with a small Teflon insert inside and no constrictor other than the rubber part. See seal #3. This one will stretch over the valve guide and still fit inside of the inner valve spring with enough working clearance.

Rubber seal with Teflon insert and one metal band -- fit 11/32" stems and stock size guides 9/16" OD:

Per John Twist, University Motors, Alma MI Ph: (616) 682-0800 Per John Twist, University Motors, Alma MI Ph: (616) 682-0800

For engine type: MGA/MGB For engine type: MGA/MGB

Felpro Umbrella oil seal SS 70373 Felpro Umbrella oil seal SS 70373

A single "S" in the part number would be "Seal" (one piece). A double "SS" in the part number would be "Seal Set" (8 pieces). On top is molded the same "PC" in an ellipse, and "BAF 110". I lost track of the packaging number, but I think this is the Felpro seal listed above under John Twist.

|

Addendum, Jan 3, 2006: It has been brought to my attention that parts currently supplied under Felpro part number SS 70373 is all rubber with no Teflon seal. I do not know if this is a recent change of spec for the part, or if I had the original number or description wrong. If you want the Teflon seal, see next item following.

|

More recently Dale Osterndorf found another number for this type seal:

More recently Dale Osterndorf found another number for this type seal:

Sealed Power ST2001 Sealed Power ST2001

At 07:10 PM 8/21/04 -0400, Gary Klein wrote:

During my search I did find an alternate source of ST2001 seals for you that is much cheaper than the Parts America link you reference.

Try https://www.rockauto.com/dbphp/prt,8,ST2001

where they are listed at $0.58 each. |

The Teflon insert has a T shape cross section, like a thin tube with a little flange around the outside at the waist line, and was just inserted into a mating nest groove in the rubber part. The Teflon bit was so small as to not be very expensive, so these were a little less than $2 each, maybe $14-$15 for a set of 8. In the end these turned out to be my favorite, both thin skirt and Teflon center seal, and also a very common part available at almost any auto parts store (but might be special order). The Teflon insert has a T shape cross section, like a thin tube with a little flange around the outside at the waist line, and was just inserted into a mating nest groove in the rubber part. The Teflon bit was so small as to not be very expensive, so these were a little less than $2 each, maybe $14-$15 for a set of 8. In the end these turned out to be my favorite, both thin skirt and Teflon center seal, and also a very common part available at almost any auto parts store (but might be special order).

The Teflon insert is so thin as to offer virtually no resistance to resizing, especially when warm, so the rubber body has no problem squeezing the Teflon bit into intimate contact with the stem for a good seal. So you have this easy to work flexible rubber body with a long wearing Teflon working edge. There is one tricky problem with installation though. When you use these seals on the MGA and early MGB valves with square keeper grooves, the little Teflon bit wants to get caught in the keeper groove when attempting to slide past it down the stem. This could damage the little Teflon bit, but even more of a nuisance is that it likes to pop out of the rubber piece, and it's not particularly easy to put it back in, especially when the rubber part is in your hand and the Teflon bit is still caught in the keeper groove on the valve stem.

But in the box with the set of 8 seals is packed a special assembly tool. This is a very thin plastic tube (with one closed end) that just slips over the valve stem to cover the keeper groove. See this tool on the valve stem in picture with seals 1 through 4. Put this little tube on the stem first, and you can slip the seal right past the keeper groove like it wasn't there. TA-DA !!! You would think that would be fine, except it's nearly impossible to disassemble it without damaging the seal. But you replace valve seals every time you have it apart anyway, so no big deal, just keep extra parts on hand, particularly to cover your tail in case you have to disassemble it for any reason while working on the first assembly. And don't try to pull the seal off of the valve stem, but pull the valve out of the guide first while the guide is still holding the seal nice and straight. After you do it a couple of times you learn to get it right the first time. And the same seal is no problem at all on the later model valves with the smaller round keeper groove.

Addendum 6/29/09:

It has been brought to my attention that Seal #4 above (Victor 8B45404 or NAPA B45404) may have a slight fitting issue when using original spring retainers (spring caps) and deleted oil deflector. The thicker rubber wall of this seal may touch and rub the inner valve spring. There is a little known fact about how the valve spring caps and oil deflectors fit. See separate article: FT-008.

There are two different spring caps with different minor pilot diameter (for the inner spring). When the oil deflector was deleted during early MGB production the pilot diameter on the spring cap for the inner valve spring was increased from 0.639" to 0.700" diameter. That change in dimension was to make up for the wall thickness of the missing oil deflector. If you toss out the oil deflector but continue to use the early spring cap, the top end of the inner valve spring can move off center as much as 1/32-inch. This is usually no functional problem at all, unless you are going to use a valve seal with very close fit inside the spring. With the "fat" valve seal it may help to replace the spring caps with the later style with larger pilot diameter to hold the spring more concentric so it may not rub on the valve seal.

Moss Motors sells only the later style of valve retainer (spring cap). They are $3.75 list, and you need 8 pieces, so it's about $30 to replace the set. If you do this, do not throw away the original parts. Hang onto the early spring caps (and oil deflectors) as they are no longer available as replacement parts and hold some value for a few people who may need them.

Addendum 10/25/17:

Another seal supplied by Moss Motors, Ltd.

Moss UK no: 12B2104

Moss US no: 290-890

Specified for 18G-18V engines. These are the engines that do not use the oil splash shield, but do use the later style spring cap with pilot diameter to match ID of the inner valve spring (or when used without inner spring as with the 18V engines). To use with MGA or early MGB engines you must delete the oil splash shield and replace the spring cap with later style having pilot diameter to match ID of the inner spring.

|

More recently Dale Osterndorf found another number for this type seal:

More recently Dale Osterndorf found another number for this type seal: