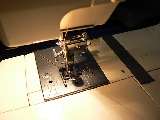

zipper foot being used as a piping foot. Sits off to one size of the seam being sewn and is adjustable. Get the heaviest duty one you can - this one is too flimsy, but I got a Singer foot which was very nice. |

double piping detail for seat sides - you can see I missed here too - this time going too far into the welting. This is why I started sewing it with the piping side up vs. the later pic showing the black side up. |

back of seam double stitched on seat back side pieces |

finished double piping for seat sides - I made the seam across here upside down for both seats - oh well. The fold should be aimed down, not up. |

restored pass side seat back with muslin "envelope" covering the horsehair padding and a new cardboard back hot glued onto the frame |

sewing the double piping to the 1" wide (finished width - leave 3/8 to 1/2" per side for seam allowance) seat sides. |

This is actually wrong - it's better to sew from the other side and let the foot run against the welting - stitch through the same seam as you used to make the welting to begin with. |

|