The MGA With An Attitude

Clutch Slave PUSHROD, Adjustable - CT-108A

See prior page for dimensions of the standard MGA clutch slave pushrod. If mechanical parts are in good condition, there should never be any reason to change the rod length.

That said, occasionally someone may report some clutch operation problem were a longer pushrod might help. Tim Carpenter has made his clutch slave pushrod adjustable. He said, "I've shortened it as much as possible commensurate with still being able to disengage but there's still some permanent contact".

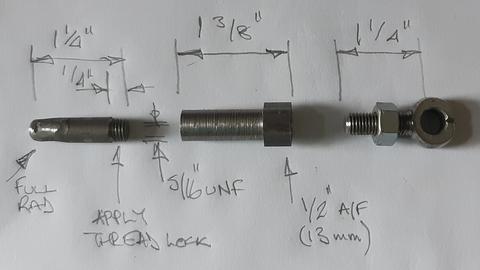

Drawing and Notes from Tim Carpenter:

Take a pushrod. Cut it to the approximate lengths shown in my sketch and run a 5/16” UNF die down each of the cut ends as shown. Please note that all the dimensions on my sketch are for the set up on my car. You may need to experiment a bit with lengths according to the engine / flywheel / clutch assembly on your own vehicle. [See standard pushrod dimensions on the prior page]. My car needed a longer pushrod than standard in order to get the clutch to disengage at all. Take a pushrod. Cut it to the approximate lengths shown in my sketch and run a 5/16” UNF die down each of the cut ends as shown. Please note that all the dimensions on my sketch are for the set up on my car. You may need to experiment a bit with lengths according to the engine / flywheel / clutch assembly on your own vehicle. [See standard pushrod dimensions on the prior page]. My car needed a longer pushrod than standard in order to get the clutch to disengage at all.

Take a piece of hex bar - mild steel / brass / whatever you have to hand - and bore and tap a 5/16” UNF thread inside it to make the adjuster. I turned off the majority of the hexagon cross section so the adjuster fits nicely inside the slave cylinder rubber outer seal. (You can braze or weld a nut to one end of the new hex part if you use round stock instead.) Permanently attach the rounded end of the pushrod inside the non-hex end of the adjuster. Thread lock works fine. Finally, run a nut onto the other part of the old pushrod and screw that into the adjuster. Don’t use thread lock on this bit. Take a piece of hex bar - mild steel / brass / whatever you have to hand - and bore and tap a 5/16” UNF thread inside it to make the adjuster. I turned off the majority of the hexagon cross section so the adjuster fits nicely inside the slave cylinder rubber outer seal. (You can braze or weld a nut to one end of the new hex part if you use round stock instead.) Permanently attach the rounded end of the pushrod inside the non-hex end of the adjuster. Thread lock works fine. Finally, run a nut onto the other part of the old pushrod and screw that into the adjuster. Don’t use thread lock on this bit.

Fit the assembly in place of the old pushrod and adjust its length using the hex on the adjuster until you take up free play in the clutch actuating arm. Nip up the nut against the adjuster to fix things. Fit the assembly in place of the old pushrod and adjust its length using the hex on the adjuster until you take up free play in the clutch actuating arm. Nip up the nut against the adjuster to fix things.

|