The MGA With An Attitude

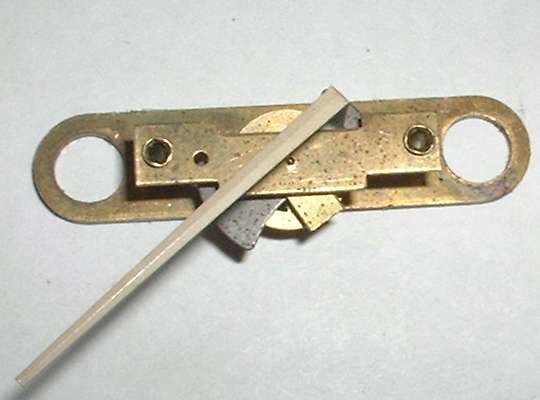

The armature assembly is composed mostly of non-magnetic brass. In fact the brass base plate does a fair job of magnetically shielding the armature from the flat coil below. The one non-brass part here is the flat steel armature shaped like an hourglass with rounded ends and positioned in line with the indicator needle. When the field magnets pull on the armature it moves, and in turn carries the needle with it.

There is no clock spring here as you may be familiar with in other rotating gauges such as the speedometer and tachometer. In the front view of this assembly you should notice a small rectangular brass tab extending downward and to the right from the center of the armature. This is a small off center weight that uses gravity to induce the needle to travel to the left (when the unit is upright). This is not an essential part of the gauge mechanism, but it does do a nice job of making the needle go to rest against the left peg when the power is off. Otherwise when the power is on the magnetic forces are substantially greater than the gravitational force, and the position of the needle will be almost entirely controlled by the action of the coils. Turning the unit sideways during operation would have only a very small affect on the indicated reading. In fact the needle can move with considerable force. When you turn on the ignition switch with more than half a tank of fuel the needle can fly across the gauge and hit the right side peg with a resounding click. Then when you switch off, the needle may return by gravity alone to rest against the left peg with only a light tick. If you invert the unit with the power off the needle will move to the opposite peg.

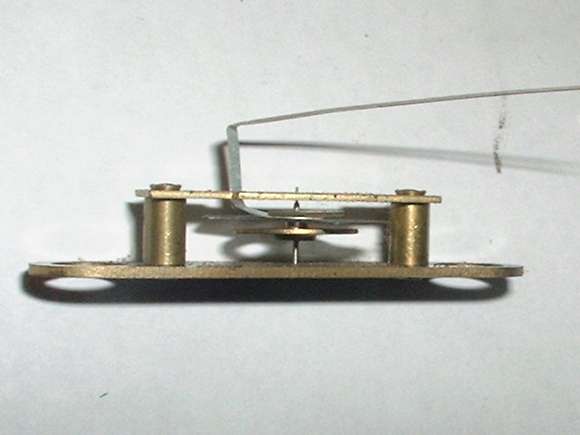

In the edge view you can see that the needle is raised a bit from the parallel plane. This happened during removal of the faceplate from the case. This is not a problem, as the needle can be easily nudged back into proper position during reassembly after installation of the faceplate. Otherwise do be careful in handling, as the needle can be easily bent. |