The MGA With An Attitude

LAYSHAFT - Undersize or Too Soft -- FT-050

BMC Part No's: 11G3030, 11G3123, 1H3305 - Rover 88G255

2-2700 Victoria British --

461-560 Moss Motors, USA

1H3305 Moss Motors, UK --

1H3305 Brown & Gammons

For all MGA.

Also MGB with 18G and 18GB engines up to H74719 Std. or H74528 O.D.

On 5/26/2012, Simon Terry in Renfrew, Ontario, Canada wrote:

"About a replacement layshaft from Victoria British. I checked the OD and found the new unit is smaller than the old. Checked your web site and see 0.6450-0.6455. My old unit is 0.6453. The new unit is 0.6420. Am I correct that this should not be used"?

You are absolutely correct, this part should not be used. This shaft has to serve as the inner race for a precision needle roller bearing. If the shaft is undersize there will be only one or two rollers touching the shaft at any given time. Imposing the full working load on only a few rollers increases the spot loading dramatically, and will also increase wear rate dramatically. This would be very hard on the rollers and shaft. If the rollers survive, the shaft will wear down to until it assumes a larger radius to touch multiple rollers simultaneously (as it should). By that time the wear would have gone through the hard surface of the shaft, and wear will continue at an accelerated rate. The early sign of wear on the layshaft is gear whine in 2nd gear as the gears become misaligned. As this continues to get worse something will ultimately break, in which case the repair gets more expensive than just replacing the layshaft and bearings.

Addendum December 2012:

On 20 December 2012, Ed Bell in Oregon, USA wrote:

"I am having trouble getting a new layshaft. The first one I purchased from a local Moss [USA] distributor was soft. He called Moss and was assured that all of their shafts were correct and Rockwelled at 52/53 Rc. That is soft enough that a file easily removes material. (I think they have left off the case hardening process). My old shaft is hard enough that a file will not mark it at all. After rejecting two more soft shafts sent from Moss in Los Angles I purchased one from Brown and Gammons in the UK. It arrived today and is properly heat treated but the diameter is 0.642 and my old one is 0.645. It is a very loose fit in the holes in the case. Can I use it or is that too small"?

It is to small for proper mating with the roller bearings. The shaft should be 0.6455-0.6450 diameter, serving as the inner race for 16.4mm roller bearings, see notes above. A bearing race (that's what the shaft is) should be 60 to 65 Rockwell (higher the better). I would not install the soft shaft or the undersize shaft.

Addendum April 2013:

In March 2013, Lee Simmonds reported receiving a "soft" layshaft from Scarborough Faire. S.F, claims they sourced that particular part from Moss Motors. Moss agrees they did sell two pieces to S.F. in November 2012 (but no telling for sure if it is the same part). Lee Simmonds commissioned a professional shop to hardness test the parts. The original layshaft removed from his worn gearbox tested hardness at 60-Rc. The replacement part tested 50-Rc. The part with 50-Rc hardness can be scratched with a file or hacksaw blade, while the 60-Rc part cannot be scratched.

On April 4, 2013, Blaine Graham at Moss Motors reports:

"I asked that five of these, at random, be pulled from stock here and tested for hardness. This was done right away. The HRC results were 49.5, 48, 49, 49, 48. The target is 50. Hitting within two points of the target is well within specifications. The one John Twist used in his video six years ago was returned to us. It tested to have a hardness of HRC 24. That was clearly unhardened".

So there is "hard", and there is "bearing hard". Rc-24 is definitely soft, not hardened. Rc-49 is hardened, but not as hard as would be desired (or required). A quick search of bearing suppliers yields a consensus that a shaft to be used as inner race for a roller bearing should be Rc-60 minimum surface hardness. While the Rockwell "C" scale for hardness is roughly linear, wear resistance is not linear. A relatively small change of hardness results in a relatively large change in wear characteristics. 50% increase in hardness can yield 50X increase in shaft life. Roughly speaking, the difference between Rc-49 and Rc-60 could yield 20X increase in wear resistance. When you invert the fraction, the difference between Rc-60 and Rc-52/53 Rc-49 could yield a 95% reduction of wear life (roughly speaking). Therefore, as a roller bearing shaft is concerned, Rc-49 may be "hardened" but is not hard enough. When the shaft can be scratched with a file or hacksaw blade, it is not Rc-60 hardness.

Blaine Graham at Moss further reports:

"When this matter came up six years ago, we set an inspection flag for these. At the time, we pulled random samples and had them tested by an outside company. When a reasonable number of orders passed muster with no issues, we stopped the random testing. .... We test every one for dimensional compliance, but not for hardness. We will not test for hardness again unless we have a reason to, as we did today".

In 2011 Moss was supplying parts that were Rc-59. Now we have the case where Moss Motors is knowingly selling parts with Rc-48 to 53 hardness thinking they are suitable as roller bearing shafts (which they are not), and they are no longer testing hardness for each new supply order. I will drop another note to Moss to see what can be done.

Addendum, April 10, 2013:

Some additional information from Lee Simmonds, after lots of phone calls searching for good parts. Found out from John Espisito of Quantum Mechanics that he returned 4 of these back to Engle Automotive in Michigan. They think maybe there is only 1 current source for these, as Jack Night Mfg in England went out of business about 3 years ago. -- John Twist at University Motors in Michigan is now furious, as he has a tranny apart now for which he will need a shaft. -- Lee Simmonds found one piece at McLeod in Arizona that has been in stock for a while and might be good. It will be hardness tested immediately upon receipt.

As of April 10, 2013, no one at Moss has yet acknowledged that Rc-49 is inadequate, and they apparently continue to sell those parts. Let the buyer beware.

Addendum, May 11, 2013:

We have a customer oriented success story. Lee Simmonds got one of the Rc-49 layshafts from Moss. He had a local heat treating facility heat treat the part properly, and it came out with Rc-62 surface hardness. It just wants a little follow up polishing to restore the luster.

So the good news is (after months of fiddling around) the metal is a good alloy that will accept heat treating to the required hardness, and Lee can get his car back together. The bad news is that a customer had to solve the problem at his own expense (while other customers are still waiting), and so far Moss Motors has not even acknowledged that there is a problem with their part (let alone fix it). As always, Let the buyer beware.

Addendum, May 16, 2013:

Matthew Randell in Adelaide, Australia wrote:

" Here is a photo of a new layshaft I removed from my '59 A. This shaft had done approx 1800 miles! I have, of course replaced it and the car is now finished; but how do I know if the shaft I have fitted is faulty"?

Hardness test before installation. The parts should be sample tested for hardness at the fabrication shop (Quality Review) after heat treating and before shipping. They should also be sample hardness tested by the resale vendor (Quality Assurance) unless they have a QA inspector in the factory to watch and verify the original test. When neither of these things happen the part gets through to the end customer, and most people will not find out about the bad part until the gearbox fails prematurely after some running time.

Addendum, June 26, 2013:

Mr. Joseph Kirsch has notified Moss Europe about their current supply of layshafts that are not hard enough.

On 21 June 2013, Joseph Kirsch wrote to Moss-Europe:

"The layshaft is not case hardened to 62Rc. When I run a file across the end it easily removes material. Could you please replace it on warranty with one that is up to the 62Rc standard".

To which Jeff Marks (R&D and Tech Support) at Moss-Europe replied:

"Our 1H3305 layshafts are not hardened to 62Rc, we would expect them to test at 54/55 Rc. I tested one in the centre along its length at 51Rc, but it must be noted that they often test at a lower figure in the centre as the hardening process puts a slight bend in the shaft which must be ground out. This final process will go through some of the hardness particularly in the middle where the bend is greater". "Our 1H3305 layshafts are not hardened to 62Rc, we would expect them to test at 54/55 Rc. I tested one in the centre along its length at 51Rc, but it must be noted that they often test at a lower figure in the centre as the hardening process puts a slight bend in the shaft which must be ground out. This final process will go through some of the hardness particularly in the middle where the bend is greater".

"The manufacturer has promised to undertake some tests, but I have not had any results from this". "The manufacturer has promised to undertake some tests, but I have not had any results from this".

Addendum, August 17, 2013:

A note from Thomas Aczel in Australia. He posted this question and few web page references to Robert Pope . Robert had been an engineer with Borg Warner, is trained in metallurgy, and was involved with the various manufacturers Borg Warner supplied, in durability testing. Robert's response follows.

"Had a quick look at one of your internet sites in relation to the layshaft hardness. Any shaft with a hardness in the 50's RC is certainly not in the running; 60-63 RC is more like it. Under 58 RC and you will start to get spalling, and over 64 is just too hard which creates micro cracks and ends up in pitting failure. At 50-55 RC the shaft has not been case hardened but could be just a plain carbon steel heat treated and tempered back too far so it won't break in half (not a good choice of steel selection by MOSS), or it could be that their provider has ground too much of the case hardening. A proper case hardened shaft should be about 62RC on the surface with a core hardness around 35-45 RC, good surface hardness with a softer core which allows it to flex under extreme conditions without breaking but retains maximum wear hardness for the needle rollers. By the way the needle rollers will be about 63-64 RC, they are generally thru hardened". -- Robert Pope "Had a quick look at one of your internet sites in relation to the layshaft hardness. Any shaft with a hardness in the 50's RC is certainly not in the running; 60-63 RC is more like it. Under 58 RC and you will start to get spalling, and over 64 is just too hard which creates micro cracks and ends up in pitting failure. At 50-55 RC the shaft has not been case hardened but could be just a plain carbon steel heat treated and tempered back too far so it won't break in half (not a good choice of steel selection by MOSS), or it could be that their provider has ground too much of the case hardening. A proper case hardened shaft should be about 62RC on the surface with a core hardness around 35-45 RC, good surface hardness with a softer core which allows it to flex under extreme conditions without breaking but retains maximum wear hardness for the needle rollers. By the way the needle rollers will be about 63-64 RC, they are generally thru hardened". -- Robert Pope

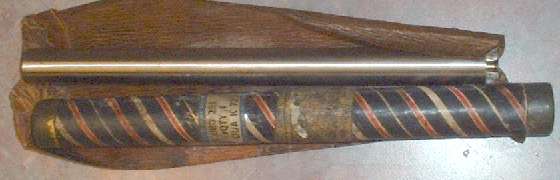

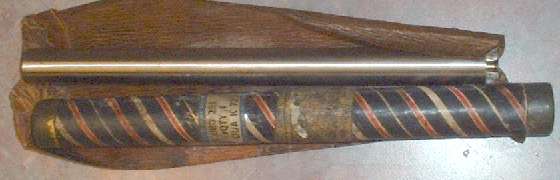

Addendum, October 8, 2013:

Another possible solution. Stanley Watkins found a new old stock original BMC layshaft on eBay. Photo included, just for grins. This one has part number 88G255.

Addendum, December 21, 2013:

Latest word is that John at Quantum Mechanics said the last batch of shafts he obtained were OK, and that they were from the supplier that Moss gets them from. John said they were RC58. So, IF (and that's a big IF) Moss tossed the ones they had in stock (or returned them) and have this new batch too, then they should be OK. I have not heard from Moss yet on the current status of their parts.

On March 17, 2014, Ryan Thompson wrote:

"Just wanted to let you know I got one from John [at Quantum Mechanics]. John noted on the invoice that he tested the shaft at 55 Rockwell".

Rats again. Last report was that they were 58-Rc, but now 55, same as last reported by Moss Motors. So much for the optimism. Stay tuned for the continuing saga.

Addendum, June 13, 2014:

On 6/13/2014, Michael Pratt from Moss Europe Ltd, wrote:

"Owing to popular demand, we have had made the MGA layshaft made from a different material and had them hardened to 62HRC. We intend to sell this part alongside our existing product. The new part number is 1H3305X (461-561 in the USA but none on order as yet from us). "Owing to popular demand, we have had made the MGA layshaft made from a different material and had them hardened to 62HRC. We intend to sell this part alongside our existing product. The new part number is 1H3305X (461-561 in the USA but none on order as yet from us).

The stock we have of 1H3305 is around 58HRC which is as near as possible to the original shafts we have in our lockup.

With the benefit of the correct laygear bearings 3H2865 (which everybody wished were available but very few have bought them now they are), the 58HRC layshaft should last as long as the original. The stock we have of 1H3305 is around 58HRC which is as near as possible to the original shafts we have in our lockup.

With the benefit of the correct laygear bearings 3H2865 (which everybody wished were available but very few have bought them now they are), the 58HRC layshaft should last as long as the original.

What with the introduction of the correct snap ring and the laygear kit, I hope we can finally put this subject to bed". What with the introduction of the correct snap ring and the laygear kit, I hope we can finally put this subject to bed".

Beware the new part is not yet in the print catalog or on the website, and the older softer parts are still being supplied under the original part number.

Addendum, July 22, 2014:

On 7/22/2014, Michael PRATT wrote:

http://www.moss-europe.co.uk/Shop/ViewProducts.aspx?PlateIndexID=24237

Will be available soon from Moss USA under part number 461-561. -- Mick Pratt

Note that the older softer shafts are still being sold under the original part number. I suspect they will continue to be supplied until inventory is depleted. Let the buyer beware. If you want a properly hardened layshaft you must order the part number for the "uprated" part. The new part number is not yet listed in the Moss USA catalogs or on the Moss USA web site.

Addendum, Aug 22, 2014:

On 8/22/2014, Ryan Thompson wrote:

462-561 Layshaft Fails Inspection

"Just got a call from Moss, and they are not shipping the 461-561 layshaft because it apparently failed inspection".

Addendum, Oct 19, 2014:

On 10/19/2014, Paul S Kaminsky wrote:

"I checked my new one from V.B. and guess, what its undersized. I ordered it about ten days ago, so that tells me nothing has happened to rectify the issue of crappy parts. It appears that Moss doesn't even sell them anymore. [See addendum Aug 22]. ....

Addendum, Jan 22, 2015:

After a few fits and starts, a couple of rejects and re-manufacture, Moss Motors UK now has new layshafts advertised as 60-62 HRC. You must order part number 1H3305X, as the softer shafts are still being sold under the original part number 1H3305. Hopefully these will be available soon from Moss Motors USA.

Addendum, March 15, 2015:

I just pulled this one out of my own gearbox. The base diameter is 0.645 as it should be. The worn sections are from front (right) to back (left), 0.639, 0.641, 0.634 diameter. Obviously gone completely through the "hard" surface and spalling on the softer material. The mating bearings were the recently common 11-roller cage bearings.

In service 8-1/2 years, 85,000 miles. To be fair, this gearbox was whining noticeably in 1st gear a year earlier with 35,000 less miles (50,000 miles then). The more recent 35,000 miles was mostly open highway cruising in 4th gear with very little load on the layshaft. So I judge this part was beyond reasonable life at 50,000 miles. With the miles I am driving these days, this part would be worn out an need changing every 18 months or so. Entirely unacceptable.

Addendum, September 8, 2015:

Last week end I removed this layshaft (below) from my MGA after 5-1/2 months and 24,500 miles in service. It is the same formula as the one above, the earlier softer shaft, mated to 11-roller cartridge bearings. I was expecting it to last about twice as long, but no joy. I really hate having to pull the engine to rebuild the gearbox twice a year due to faulty parts.

This time the replacement parts are (supposed to be) the harder layshaft 60-Rc and original type full compliment needle bearings. Also a new laygear, very good used 1st gear, and all new synchro rings. This is about as good as an MGA gearbox rebuild gets, so I am looking forward to seeing how long the original type needle bearings and properly hardened layshaft may last.

This time the replacement parts are (supposed to be) the harder layshaft 60-Rc and original type full compliment needle bearings. Also a new laygear, very good used 1st gear, and all new synchro rings. This is about as good as an MGA gearbox rebuild gets, so I am looking forward to seeing how long the original type needle bearings and properly hardened layshaft may last.

Addendum, May 15, 2018:

2-1/2 years on, we have been nursing this gearbox for a long time to see if it might be possible to get 100,000 miles out of it, but no such luck. At 90,700 miles we stopped at a friend's place in Kenly, NC, because there was no way this was going to make it back to Chicago. On disassembly it disclosed the worst worn layshaft I have ever seen in my life, with the end plates of the needle bearings wearing deeply into the layshaft. not only the failed shaft and bearings, but it also took out the new laygear that was installed last time around (and 1st gear along with it). Calculating the wear rate around 0.005"/10000 miles, this failed layshaft was obviously no better than the one before it, and certainly not as hard as was advertised.

This time I definitely installed a part with the new part number for "uprated" layshaft, along with new OEM full compliment needle bearings, and another new laygear. All I can say at this point is, cross fingers and hope this one may last a little longer.

Addendum, October 19, 2020:

After a little prompting from a friend, I was encouraged to post an update here. The gearbox has now accumulated 68,000 miles in the past 2-1/2 years, and it seems to be holding up fairly well, no funny noises yet.

Currently Moss UK and Moss USA show the original part number layshaft to be NLA, and they are only selling the layshaft with the newer "X" part number. I suppose that means they have finally sold out the old part number faulty soft shafts (and I pity all the people who were suckered into buying the faulty part just because it was cheaper). At last report the "better" part was still not 60-Rc minimum, but at least a lot better than the older ones. I'm still testing to see if it can make 100,000 miles, while changing oil in the gearbox every 12,000 miles to be sure it gets a fair trial.

Addendum, September 12, 2022:

More prompting, and I have another update. My gearbox has now accumulated 98,000 miles in 4-yr 4-mo since May 2018, and it is still doing well, slick shifting and no abnormal noises. I recon it is going to last quite a lot longer. So it looks like we have landed on the correct recipe, just build it like it came from the factory, and it will do just fine. The layshaft needs to be 60-Rc, and it needs the original type full compliment 18-needle bearings (3 is sufficient). Pay the piper, and get the good parts. If in doubt, have the new layshaft hardness tested before installation. - Barney

|